Quality

- ISO 9001 Quality Management system

- IATF 16949 – Automotive Area

- AS/9100 – Aerospace Area

- ISO 13485 – Medical Devices Area

- ISO 22000 / HACCP / BRC /IFS – Agribusiness Area

- ISO 17025 – Laboratory Accreditation

ISO 9001 – Quality Management System

To operate in the European and international market it is essential to obtain a Quality Management System Certification and manage activities within its organizations.

The new edition of ISO 9001 suggests and stimulates the integration of the Quality Management System with the ISO 14001:2015 Environmental Management System and, where it is appropriate, with Safety Management System , hygiene and for the guarantee of “ethical behavior” in the workplace.

MAJOR NEWS INTRODUCED BY ISO 9001

- Application of the “High Level Structure” (HLS) (new structure, according to the ISO annexe SL directive)

- Priority to obtaining Quality Management System results

- Better consideration for the organizational context, important aspects, understanding of the needs and expectations

- Risk-oriented approach to support and improve Quality Management System planning and processes management

- Strengthening of management responsibilities (staff, context, strategy, process management, results, integration)

- Clarifications regarding the definition of the scope of the management system

- Less emphasis on documents

- Better applicability to service providers

- Emphasis on the following aspects:

- Processes conduction (goals, performance indicators…)

- Knowledge management

- Control level on external performance (products, services, processes)

- Post-delivery activities

- Maintaining surveillance and measurement resources

THE M&IT CONSULTING APPROACH

The M&IT consulting program is characterized by strong pragmatism, result orientation and widespread use of it technologies and support aimed at streamlining and making activities more effective than traditional approaches.

The Quality Management Systems Development/Adjustment Advisory Program is developed as follows:

- Mapping/analyzing processes and activity flows;

- Analysis of the organizational context, strengths and weaknesses, opportunities and dangers, understanding of the needs and expectations;

- Risk analysis and assessment according to ISO 31000;

- The adjustment/issuance of system documents (Manual and Procedure) and its module to the new ISO 9001 standard;

- Planning and conducting audits to assess the adequacy and effectiveness of the Quality Management System (with a particular focus on the processes considered most critical/important);

- Support for the identification of the corrective and preventive actions necessary to remove the causes of non-compliance resulting in verification of their implementation and effectiveness;

- Support for the planning and registration of training interventions related to the SGQ;

- Verification and improvement of the performance indicator system (KPIs) consistent with business process improvement priorities;

- Support in setting annual improvement targets/projects in relation to the Business Process Performance Indicators (KPI) system;

- Support for monitoring the progress of improvement projects and achieving the objectives set;

- Conducting and verbalizing the Management Review.

- Support during audits conducted by the chosen certification body and management of relationships and communications with the same.

RESULTS

The development and certification of the Quality Management System, if oriented to effectiveness and efficiency lead to the following results:

- Best image

- Process rationalization, achieved through the analysis and definition of management and operational procedures

- Organizational clarity in terms of roles, authority and responsibilities

- Reduction of “non-quality” costs through prevention activities that are one of the key elements of management systems

- Human resources development, through awareness and training focused on Quality, Environment, Health, Safety and Social Responsibility.

M&IT MODEL FOR THE DEVELOPMENT OF RISK MANAGEMENT SYSTEM

In Italy and abroad, companies are experiencing a moment of great awareness of the importance of a careful and effective risk management policy, which can lead to losses or damages and, consequently, affect profits, the company’s market shares or damage its image.

The company runs a lot of this kind of risks: just to give few examples: from the burning of plants to the theft of goods, from the injuries of personnel to damage to third parties, from the damage and costs as a result of environmental pollution, to the interruption of activities of one or more plants.

To assess and then treat these risks, the “RISK MANAGEMENT” methodology can be supported, which leads us to develop a risk management system present in all business areas.

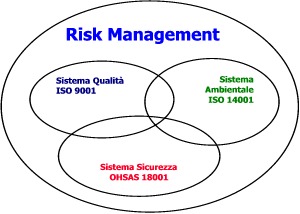

Building a Risk Management system means developing a system of identifying, evaluating and managing events and actions that can affect an organization’s ability to achieve its goals.

Starting from the identification and assessment of all risks applicable to a company, we define the operational modalities of prevention, control and risk management, that can be integrated into an existing quality, environment and safety management systems. As shown in the figure below, a risk management system can include all three management systems.

The Risk Management developed by M&IT Consulting, is based on the management of the following aspects:

- Preventing environmental pollution

- Emergency management

- Workers’ safety and health

- Fire Prevention

- Maintenance and control of electrical and mechanical systems

- Management and organization of company infrastructure and equipment

- Information security

- Management of business risks related to D. Lgs. 231/2001

(* required fields)